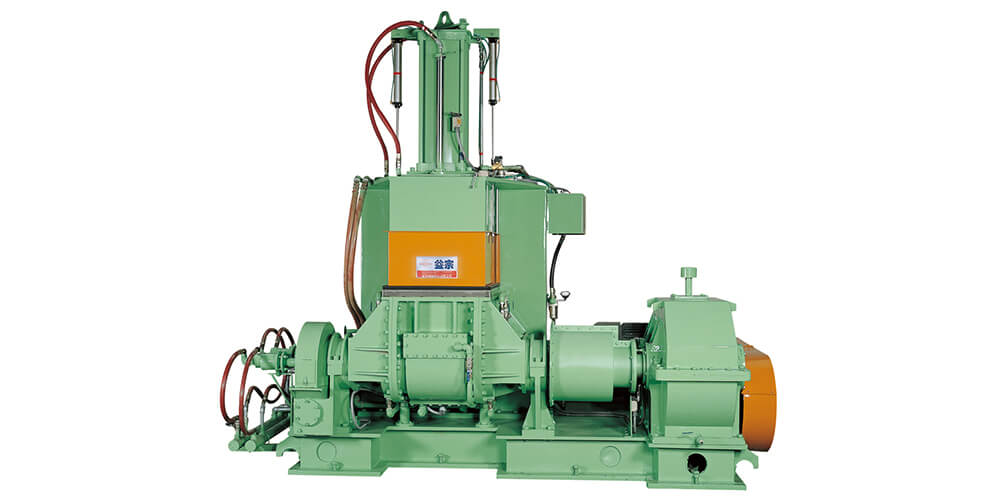

Dispersion Kneader

Dispersion Kneader HD Type

This Dispersion Kneader is suitable for processing single or mixing numerous raw materials, including natural, rubber, syntetic rubber, plastic and more. The model has a sturdy construction.

It features a large mixing capacity, high speed, excellent performance, fully automated temperature control, a simplified operating process, labor savings, and stable product quality.

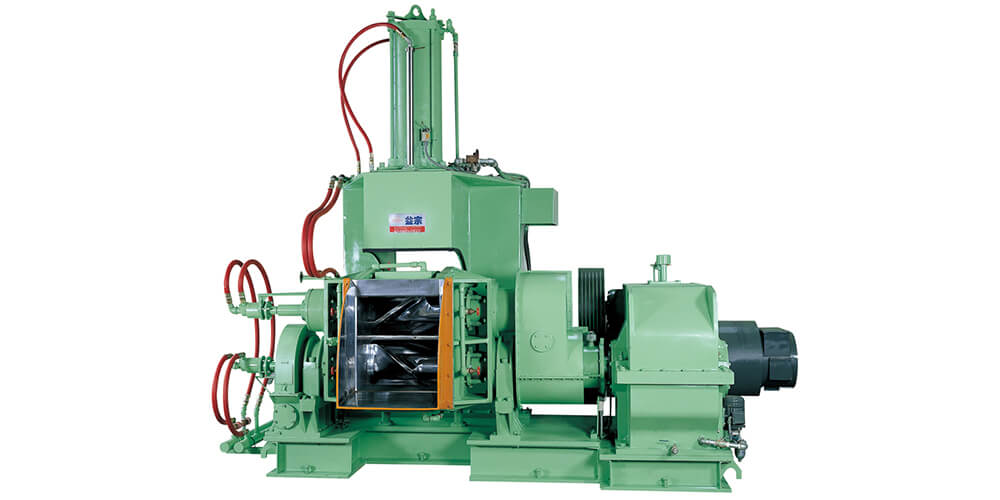

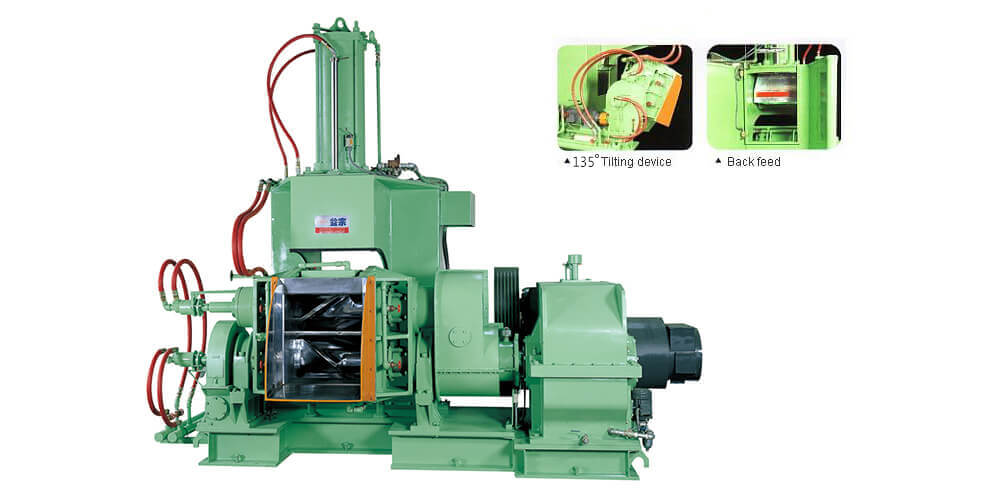

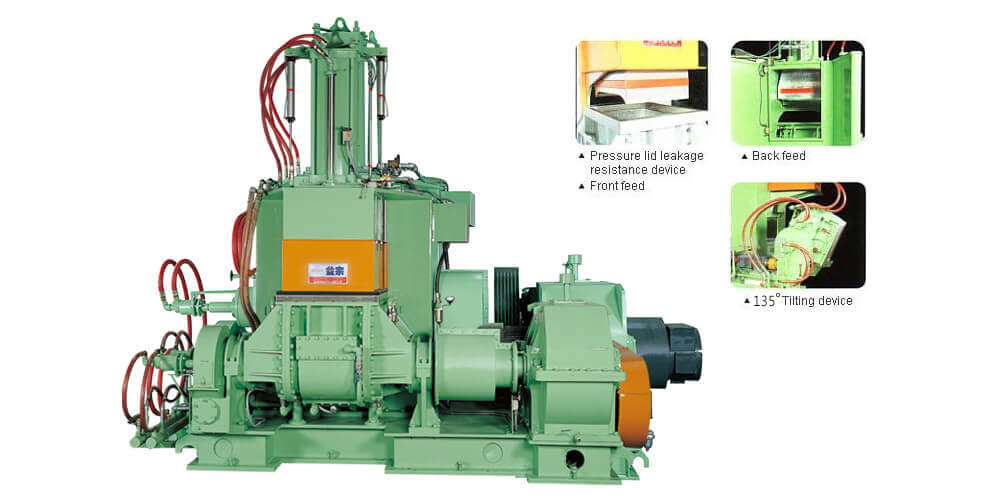

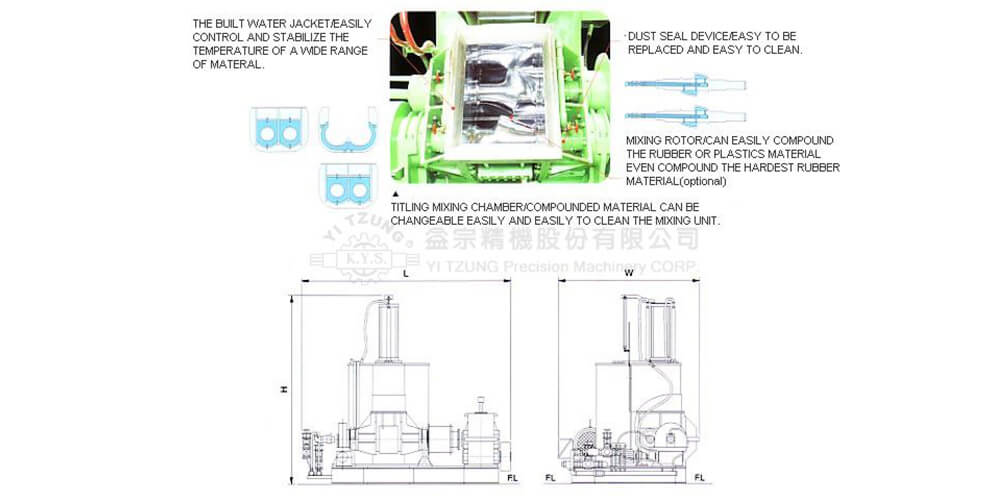

A rear input, front output design results in smooth-flowing production and back window design allows observation of mixing conditions. Its sealed mixing chamber ensures safe operation and eliminates the environmental pollution problem. The mixing chamber has a 135° dumping inclination for easy removal and changing of coloring ingredients.

The machine is easy to install and requires no special foundation. Production can be changed at any time.

It features a durable, low failure rate, and easy maintenance. It’s a ideal mixing equipment.

- It is an idea equipment for development of the latest rubber or plastic.

- The design with high dispersion for rotors are suitable for the compound of high quality material.

- The mixing chamber is constructed with heat resistance, wear out resistance and anti-corrosive. (optional)

- Special design on dust stop ring can efficiently prevent leakage from mixing chamber.

| Model | YK-35HD | YK-55HD | YK-75HD | YK-110HD | YK-150HD |

|---|---|---|---|---|---|

| Mixing Capacity(L) | 35 | 55 | 75 | 110 | 150 |

| Main motor horse power (HP) | 50-70 | 75-100 | 125-150 | 150-200 | 200-300 |

| Tilting motor (HP) | 3 | 5 | 5 | 5 | 7 1/2 |

| Air compressor (HP) | 5 | 7 1/2 | 7 1/2 | 7 1/2 | 7 1/2 |

| Exhaust fan | 1 | 1 | 1 | 1 | 1 |

| Material feed | BACK | BACK | BACK | BACK | BACK |

| Temp control | AUTOMATIC | AUTOMATIC | AUTOMATIC | AUTOMATIC | AUTOMATIC |

| Control panel position | BACK | BACK | BACK | BACK | BACK |

| Rotors revolution | 30/25 | 30/25 | 30/25 | 30/25 | 30/25 |

| Normal air pressure | 6-7kg/cm2 | 6-7kg/cm2 | 6-7kg/cm2 | 7-8kg/cm2 | 7-8kg/cm2 |

| Outline Dimesion m/m(for reference) | |||||

| H | 2,890 | 3,076 | 3,150 | 3,600 | 4,100 |

| W | 1,800 | 2,130 | 2,400 | 2,490 | 3,050 |

| L | 3,669 | 4,010 | 4,200 | 4,930 | 5,480 |